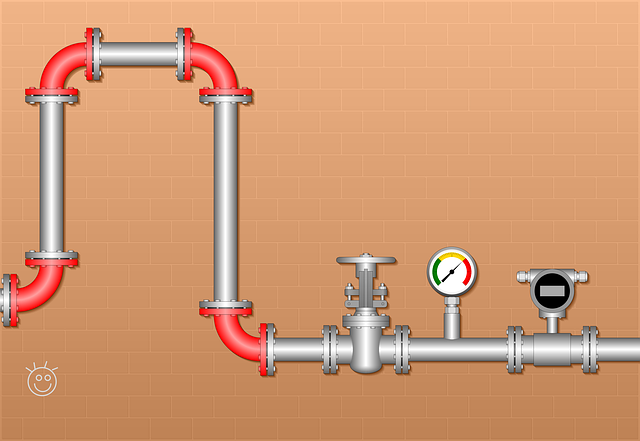

The Importance of Accurate Flow Measurement in Industrial Processes

Accurate flow measurement plays a pivotal role in industrial processes. It’s not just a technical necessity; it’s the backbone of efficiency, safety, and cost control. Without precise measurements, industries risk wasted resources, operational hiccups, and even catastrophic failures. Whether it’s tracking fuel usage or maintaining production quality, flow meters are essential tools that ensure everything flows—literally and figuratively.

Why Accurate Flow Measurement Matters

In any industrial setting, fluids—whether liquids, gases, or a mix of both—are in constant motion. To keep things running like clockwork, understanding the exact flow rate is crucial. Here’s why:

- Avoid Resource Waste: Imagine pouring money down the drain. That’s what happens without accurate flow measurement.

- Ensure Process Efficiency: Precision prevents downtime, production losses, and potential safety risks.

- Stay Compliant: Regulations demand strict adherence to environmental and operational standards.

Precision Tools for Measuring Fuel Flow

Among the various types of flow measurement tools, fuel flow meters stand out. They’re indispensable in industries where every drop of fuel counts. Whether it’s powering a plant, running a fleet, or fueling heavy machinery, fuel meters ensure real-time monitoring and precise data analysis. This not only optimizes fuel usage but also helps cut costs and reduce emissions—a win for businesses and the environment.

Types of Flow Measurement Techniques

Flow measurement isn’t one-size-fits-all. Depending on the application, industries use different methods to get the job done. Here’s a breakdown:

- Differential Pressure Flow Meters: These measure flow rates by detecting pressure drops. While reliable, they require regular calibration and maintenance.

- Positive Displacement Flow Meters: Think of these as mechanical counters that measure fluid volume. They’re highly accurate but can be bulky and less suited for high-speed applications.

- Electromagnetic Flow Meters: Perfect for conductive fluids, these devices offer high accuracy and minimal maintenance. However, they don’t work with non-conductive fluids like oil or gas.

- Ultrasonic Flow Meters: Using sound waves, these meters provide non-intrusive measurements, making them ideal for large pipelines or situations where minimal disruption is needed.

- Coriolis Flow Meters: The gold standard in flow measurement, especially for fuels. These meters measure mass flow and density, offering unmatched precision.

Real-Life Applications of Accurate Flow Measurement

Let’s look at how accurate flow measurement transforms industries:

- Energy and Power Plants: In power plants, precise fuel flow measurement is essential for optimizing combustion processes. By tracking every unit of fuel, operators can reduce waste, cut down on emissions, and maintain regulatory compliance.

- Oil and Gas Sector: From extraction to refining, flow meters are indispensable. They monitor fuel usage, detect leaks early, and ensure the safety of operations. A small undetected leak can escalate into an environmental disaster—accurate flow measurement prevents that.

- Automotive and Fleet Management: Fleet managers rely on fuel meters to monitor consumption, spot inefficiencies, and lower operational costs. Real-time data helps optimize routes, reduce downtime, and maintain vehicles more effectively.

- Manufacturing and Processing: Industries like pharmaceuticals, chemicals, and food production require precise flow measurements to maintain product quality. Over- or under-delivering fluids can disrupt entire production lines, leading to losses in both time and resources.

- Environmental Applications: Accurate flow measurement helps industries monitor and minimize their environmental footprint. By optimizing fuel and resource usage, companies can meet sustainability goals while improving profitability.

Advanced Insights into Flow Measurement

While the basics of flow measurement are widely understood, delving deeper unveils its broader significance. Here are some advanced considerations:

- Integration with Automation Systems: Modern industries heavily rely on automation to streamline processes. Advanced flow meters, including flow meters for fuel, seamlessly integrate with automation systems, offering real-time data that can be used for predictive maintenance, optimization, and reducing operational downtime.

- Internet of Things (IoT) in Flow Measurement: IoT-enabled flow meters are revolutionizing industrial processes. These smart meters, such as flow meters, provide remote monitoring, data logging, and analytics. By analyzing trends over time, industries can make informed decisions about resource allocation and process improvements.

- Calibration and Maintenance: Even the most advanced flow meters require regular calibration to ensure accuracy. Flow meters are no exception and must be regularly maintained to prevent inaccuracies that could result in inefficiencies or safety concerns.

- Industry-Specific Customizations: Not all flow meters are created equal. Custom solutions tailored to specific industries, such as flow meters in aviation or high-pressure meters for hydraulic systems, can significantly enhance operational efficiency.

Conclusion

In the fast-paced world of industrial processes, accuracy isn’t a luxury—it’s a necessity. Flow measurement, especially with tools like fuel meters, ensures that resources are used efficiently, safety standards are upheld, and environmental compliance is maintained. Whether it’s a power plant, a fleet management operation, or a manufacturing unit, accurate flow measurement is the unsung hero behind smooth operations and cost savings.

Ready to take your industrial efficiency to the next level? Discover cutting-edge solutions with AIC Systems Inc. Their advanced flow measurement tools and expertise can revolutionize your operations.